Dee:

I sat with this and made some notes (on paper) last night. I'll drop them in place below.

Bob

-------Original Message-------

Date: 12/10/2006 3:15:03 PM

Subject: Glue

Bob, do you agree with this gentlemans statements?

The other difference you will notice in the way I build is that I don't use the CA adhesives that are popular these days. I use Elmer's Carpenter's Glue (another good brand to use is Titebond II) for building.*My vote here is in favor of Titebond II. There are others, but this one I can guarantee is good. For steps in this kit like installing the CA hinges I will use CA*Sure; designed to use thin CyA's wicking (Capillary) action., but for the main build I will use Elmer's and epoxy for the build. I used to use CA when I build, but I made the decision to switch to wood glue about 2 years ago. My main reason for switching was the fumes, they can be very harsh on your eyes, nose,and lungs and I just got tired of the discomfort.*The fumes can be a problem, but there are non-fuming CyA's which cost double. Generally CyA's are brittle, so not good for some things. When you build with CA your parts have to be positioned correctly when you apply the CA, otherwise your part is stuck where it is out of place.*In any case, make parts fit first, then glue. When I use CyA, I fit a part, put it in place, then give it some thin CyA and watch it wick into the joint. This only works for close-fitting parts. Don't use thick gap-filling glues or CyA to fill gaps, as I said, fit them first, then glue. With wood glue you have time to get your parts positioned correctly before the glue starts setting. Also, CA will make the wood it is applied to very hard and when you start sanding it can be difficult to get a good finish. *True, depending on the weight (hardness) of the balsa being used. The surrounding wood will sand away quicker than the wood with CA applied to it. *Nearly without exception, sand structures with a sanding block.With wood glues, the glued joint will sand just like the wood itself.

Raining here again.

Dee

Depending on what you decide to build, here's a suggested arsenal to have on hand. Buy small sizes, at least to start, until you find what you like, then according to taste, application, and how much you may be building.

CyA:

a) Thin

b) Medium

c) don't bother with thick; you should not need it.

There are numerous good brands, though most all of it comes from just a few sources. Satellite City's

'Hot Stuff' I can guarantee is good, Bob Smith's, the stuff Rockler sells to name a few.

General wood structure:

Titebond II. Sometimes it's appropriate to thin it some - uses water...a little thins it a lot.

Wood to carbon fiber:

Use medium CyA. Spread it thinly and press the parts together until cured.

Epoxies:

Use it for firewalls and heavy duty structures, especially around the nose and points of wear and

exposure to fuel and oil.

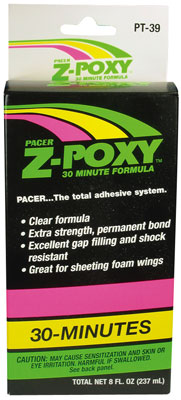

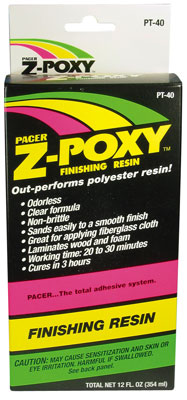

a) Thin stuff for fiberglass application, like Z-Poxy from Zap

a waxy surface. It should be wiped clean with solvent (like Stoddard, 'paint thinner', turpentine or Naptha before the next step. Naptha is my favorite for this application. After a wipe down, the surface should be sanded before primer/paint, or a second layer of fiberglass cloth.

b) Thicker stuff for construction applications

'gluing' things together like those rock-hard maple motor mounts to plywood members.

c) There's five minute stuff, too. You might want to keep a small amount in the field box for those things you want to fix while out flying where CyA isn't the best choice. The five minutes is working time, not time it's safe to go flying again. More like thirty, and that's on a warm day.

And an afterthought that should be up front! You DO have 3M's 77 spray don't you? OK, go buy some, you NEED it for various insundry things that just can't be accomplished with anything else.