Cox Medallion .051 NFFS Special

|

Free .pdf saw owner's manual: Write Bob@theaerosmith.com or download here:

Per Bill Wilson, Dremel expert: "The 580-2 is a later model and has a few minor upgrades. The Motor shaft and pulley diameter is approx. 1/8 thicker than the earlier 580 model (.2500" and .3143") Also the front hub with gear has a baked on Grey enamel rust proof finish. The cheap chrome front knob on the 580 model tends to be prone to rust. The hardware screws that attach the motor frame assembly are also anodized screws rather than chrome screws. Other than these differences the saws are identical in every other way." To be clear: Early model is model 580 and has RED sticker and .2500 shafts. Late model is 580-2 has black sticker and larger .3143 shafts. My .pdf manual is from a model 580-2, but it's perfectly fine for reference for a model 580 saw-Bob@TheAeroSmith.com Repairs: http://karincorbin.blogspot.com/2009/07/ye-olde-dremel-table-saw.html Carbide blades: If you don't do ANYTHING else to you your Dremel saw, buy carbide blades for it. They are the single-most huge improvement you can make to it, a sound investment. See details about carbide blades, ordering from me and others, etc., on the Dremel Accessories page. More about blades: 310 tooth blades: if you're a train or model ship buff, or do some other work requiring doing really fine cutting, tiny stuff, and require a jewelery blade like the one MicroMark sells, their 310 tooth, hollow-ground, HSS blade at about $40 + tax and shipping, I might suggest an alternative. Personally, I use and recommend blades of known industrial quality. These are available, Made-in-USA no less, for a good deal less, as well as imports for slightly less, also of known high standards. A blade from a well known and respected US brand (Malco), exactly the specifications as MMs can be found here, a place I buy from for my shop often, about $30 each:

Replacement BELTS: You NEED to replace your belt if you're running an original type. I recommend these highly: Zimbyo seamless belts, only ones I've seen. Smooth running. The belts are only $7.50 and $2 to ship (US). I'd get two, a lifetime supply. I've sent hundreds of people here, never heard a bad word. Also has printed copies of the manual for sale in case you don't want to print your own from my free .pdf...has blades, too, but I wouldn't want you to know that. (His 36 tooth blade is excellent...see the Accessories page.) Link for the seamless belts, blades and more:

Be sure to look here for some mind-boggling, super quality modeler's tools made by modelers for modelers: http://www.byrnesmodelmachines.com/tablesaw1.html Jim Byrnes saw fully equipped isn't cheap and it shouldn't be. It is billet aluminum, CNC made right here in the USA by Jim. It has some extraordinary options available. It doesn't feature the standard tilting arbor a Dremel does, but an (optional-$125) tilting table that I understand isn't nearly as convenient to use; has to be mounted to the machine to make angle cuts rather than just crank over the blade. Still, a superb machine capable of super-precision work. He has some other items worth looking at, too. Neat stuff! I have feedback the new (2014) MicroMark MicroLux Digital table saw is really something. The base machine is $379. Some accessories available, too. A bit larger than the Dremel now, variable speed, cogged belt drive, digital fence, lots of great features. It comes with a coarse 24 tooth carbide blade, a finer one in carbide not offered, but I found Proxxon.com carries a 36 tooth carbide that's perfect-part number 28732; $38 and shipping. Check out this baby. Here's the link: http://www.micromark.com/microlux-digital-table-saw,11530.html From Bill: "The new Microlux saw is quite a bit larger than the old model and larger than the Dremel. They have a variable speed cog belt drive system and with the new design, the belts are very easy to change. I like the extension table and digital fence, plus it has a lock-in slide rail for the miter gauge with an adjustable fence." See the page with more photos of the saw modifications. If you don't do anything else for your saw, get carbide blades...and buy a spare belt. The Accessories page has links to several sources of carbide blades, including me. You can find belts a few places, but I highly recommend the Zimbyo seamless belts and have good feedback. Smoother running than standard belts. Link on the Accessories page. Other items of interest to Dremel owners: 11-2015 Berg went away SEE BILL WILSON for cogged belt drives. William Berg Co has toothed pulleys and belts. (see below). I'm currently looking (late March 2014) into a source for the CORRECT replacement motor. There are several out there that fit but are under RPM, don't pull enough amps, and worse, turn the wrong direction. The 580 and 580-2 motors have different shaft sizes, too, but the specs are otherwise identical-a 1/4 shaft motor can be bushed to fit a 580-2's .3143 pulley bore if need be. I'll post part numbers, prices and ordering information here when I nail it down. (4-25-05)

Toothed belts and pulleys:

This guy has some NEAT tools!!

Here are some modifications The AeroSmith found most useful. (See Dremel Photo Page) 1) Mounted to 3/4" Marine plywood base. Questions or comments/corrections/suggestions, drop me a line, please.

|

||

|

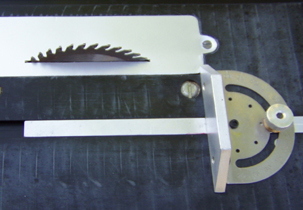

Here, the micro-adjusting fence - strips cut to within a thousandth are possible with ease. |

|

|

Right, the modified Dremel Miter Gage I did. (Please look for photo on lower right) The thick, and taller aluminum block is screwed onto to original Dremel steel backing, then trimmed 90° to the table on the milling machine. The stamped steel tongue has been replaced with a close fitting aluminum one seen here. (See Bill Wilson's great one for sale on the Dremel accessories page). |

|

|